Zhongtuo Shutter door U channel roll forming machine

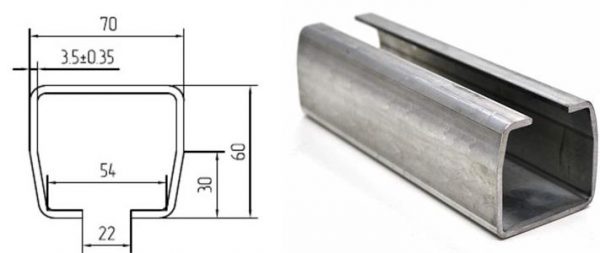

Shutter door U channel roll forming machine is designed to make the shutter door channels in batch fully automatically. Shutter door U channel rolling forming machine, it is also called U channel guardrail rolling forming machine.The function is U channel guardrail is that it is for fixing the shutter door to the right direction and then when make shutter door up and down, that will be quite easier.

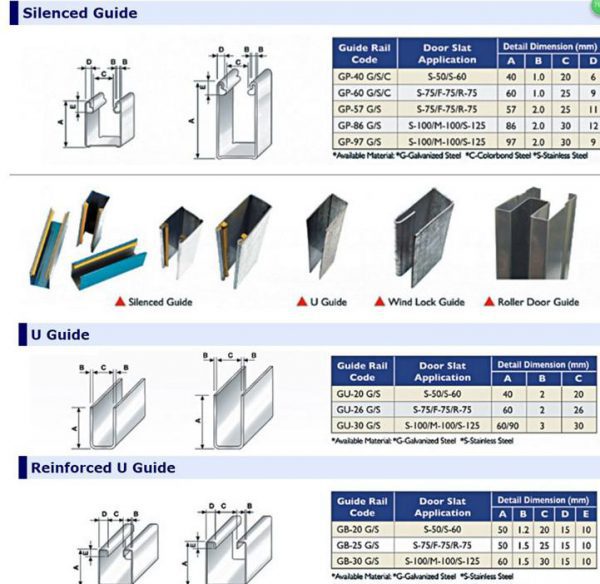

For the guardrail of shutter door,U channel is one type, different area and countries have different ideas. Here l will take some of for your reference.

And also there are many others types:

In the following articles, we will share more machine information about those profiles.

Shutter door U channel roll forming machine :

Here are some machine parameters for your reference:

Uncoiler: Manual Uncoiler

Loading Weight: 3T

Inner Diameter: 480-520mm

Outer Diameter: Max 1250mm

Leveler: with a Feeding Guide Unit

7-Roller Leveler: 3 rollers up and 4 rollers down with no power

Leveling Thickness: 2mm maximum

Diameter of Leveling Roller: 76mm

Main Structure of the Machine: 36# “H” Beam Steel

Rolling Stations: 18 stations

Forming Speed: Approx. 8-12m/min

Diameter of Shaft: 65mm

Material of Shaft: 45# steel with heat treatment

Material of Roller: Gcr15 Bearing Steel

Transmission: Chains-bracket

Main Motor Power: 11KW (subjected to final design)

Cutting: Hydraulic cutting

Cutting Length and Quantity: Clients can set the required length and quantity on the PLC touch screen

Electrical Motor Power: 3KW (subjected to final design)

Tolerance of Cutting Length: +/-2mm

PLC Control Box: 700mmx1000mmx300mm

Computer Control System: Panasonic PLC

Encoder: Omron Brand

Voltage: 380V, 50Hz, 3 phase

More details of the machine pictures for your reference:

ZHONGTUO U channel rail rolling machine can benefit you in the following aspects:

- Use world famous brand for the machine elements for easy to use and long time to use.

- Use the servo motor for flying tracking and inhance the working speed to 25 to 35 meter per minute.

- Use big hydraulic valves for shearing more powerful and big volume.

- Use GCR12mov as the roller material, it is hard enough to handle the hard material.

For this machine, if you want to know more information, please contact us at any time.